1.5-Meter Giant PCBs: When Circuit Boards Break Conventional Dimensions, Challenges and Opportunities Coexist

1.5-Meter Giant PCBs: When Circuit Boards Break Conventional Dimensions, Challenges and Opportunities Coexist

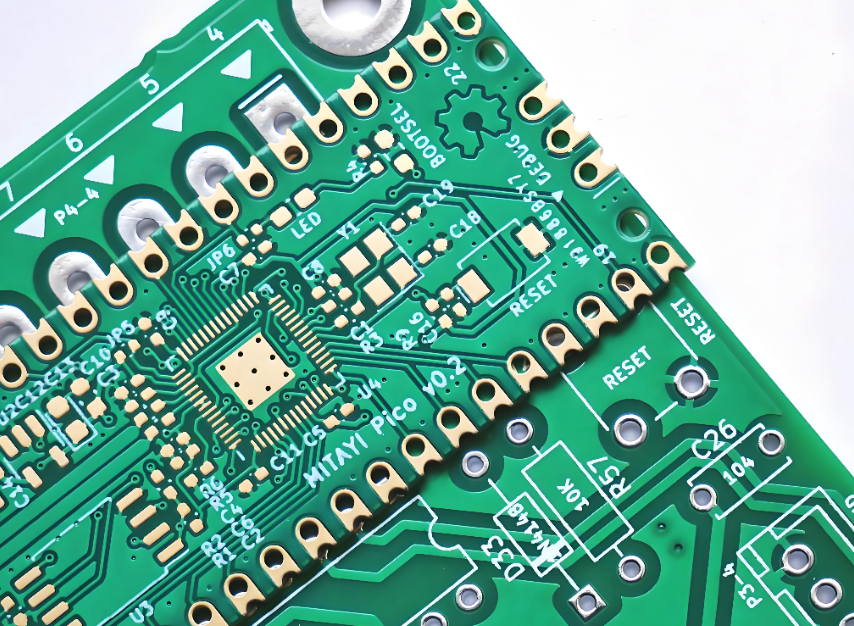

In the world of electronic engineering, printed circuit boards (PCBs) are typically measured in centimeters or tens of centimeters. But when a PCB reaches 1.5 meters in length—roughly the height of an adult—we enter an unusual field of engineering. These super-sized PCBs, which we call "Giant PCBs," are quietly changing the game rules across multiple industries.

A Design Philosophy That Breaks the Mold

Traditional PCB design follows the principle of "smaller and denser," striving to integrate more functions into limited space. The 1.5-meter PCB does the opposite; it aims not to "shrink" but to "expand." This expansion is not mere scaling up; it represents a completely new philosophy of system integration.

Imagine, in the field of LED displays, a single 1.5-meter PCB can seamlessly cover the entire display area, eliminating the visual gaps caused by splicing multiple smaller boards. In industrial control systems, a PCB of this size can integrate distributed sensors and actuators onto a single platform, significantly enhancing system reliability.

Engineering Challenges and Innovative Solutions

Manufacturing a 1.5-meter PCB is no easy feat; it presents engineers with multiple challenges:

Material selection becomes the primary challenge. Substrates of such large size are highly prone to warping and deformation during production and transportation. Advanced composite materials and high-rigidity substrates become essential, as they can remain stable under thermal and mechanical stress.

Production processes need redesigning. Conventional etching and plating equipment cannot handle boards of this size, requiring customized production line modifications. Even basic processes like exposure and development become complex—how to ensure uniform distribution of chemicals across the entire board? How to guarantee consistent etching precision in every zone?

Thermal management is another major challenge. Large size means greater power dissipation and more complex thermal expansion issues. Engineers have developed special thermal relief designs and zoned cooling solutions to ensure even heat distribution.

The testing phase is equally tricky. Traditional bed-of-nails testing is unsuitable, and flying probe testing struggles to cover the entire board due to travel limits. This has spurred the development of new distributed testing systems and machine vision-based inspection solutions.

Innovative Application Scenarios

Despite numerous challenges, the unique advantages of 1.5-meter PCBs make them indispensable in specific fields:

In high-end commercial displays, seamlessly tiled LED screens are becoming market favorites. The 1.5-meter PCB eliminates the physical seams of traditional multi-board splicing, enabling a truly seamless visual experience and providing unprecedented display effects for advertising media and stage backgrounds.

Industrial automation is another key application. In large production lines, the 1.5-meter PCB can serve as a "backbone board," integrating motor drives, sensor interfaces, and communication modules into one unit, simplifying wiring and improving system reliability.

The new energy sector also recognizes its potential. In solar inverters and large battery management systems, the 1.5-meter PCB can better match the layout requirements of power modules, optimizing energy conversion efficiency.

Future Outlook

With advancements in materials science and manufacturing technology, 1.5-meter PCBs are moving from specialized applications into broader fields. The maturation of flexible substrate technology is making "rigid-flex" combinations in超大尺寸PCBs a reality, further expanding their application boundaries.

Meanwhile, design tools are also evolving. Traditional EDA software often struggles with designs of this scale. New generations of distributed computing and cloud computing are changing this landscape, allowing designers to handle giant board designs more efficiently.

Conclusion

The 1.5-meter PCB represents the attempt of electronic engineering to explore larger scales. It is not merely a breakthrough in size but a comprehensive innovation in design philosophy, manufacturing processes, and system integration methods. In this era of booming IoT, smart displays, and Industry 4.0, these unconventional PCBs are redefining what is possible, challenging the limits of engineers‘ imagination.

As we stand at the crossroads of technological development, the 1.5-meter PCB reminds us: sometimes, the breakthrough lies not in making things smaller, but in thinking bigger.