Tg170 PCB: The High-Performance Circuit Board Foundation Born for Harsh Environments

Tg170 PCB: The High-Performance Circuit Board Foundation Born for Harsh Environments

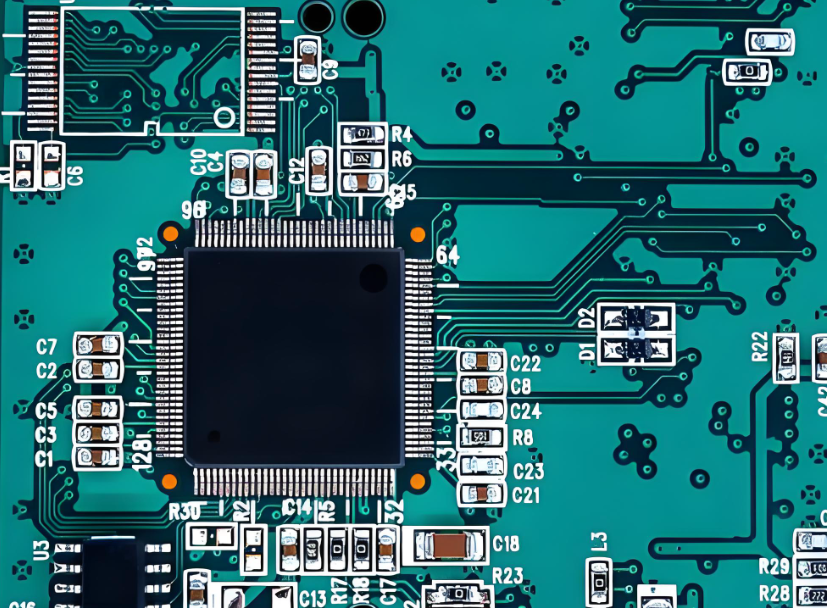

In today‘s rapidly evolving electronics industry, devices are becoming smaller, more powerful, and operating in increasingly harsh environments. Traditional standard PCBs (Printed Circuit Boards) may "fail under pressure" at high temperatures, leading to performance degradation or even failure. At this point, a high-performance material called Tg170 PCB stands out, becoming a key technology to address these challenges. This article will delve into what Tg170 PCB is and why it holds an indispensable position in the field of high-end electronics.

1. What is Tg? Why is it so important?

To understand Tg170, one must first grasp the concept of the Glass Transition Temperature (Tg).

-

Definition of Tg: Tg is the critical temperature point at which the substrate material (usually a polymer like epoxy resin) transitions from a rigid, brittle "glassy state" to a soft, elastic "rubbery state." It is not a melting point but a phase transition point.

-

Importance of Tg: When a PCB‘s operating temperature exceeds its Tg value, the material undergoes a series of adverse changes:

-

Decreased Mechanical Performance: The board softens, reducing strength and hardness.

-

Increased Thermal Expansion (Z-axis): The coefficient of thermal expansion, particularly in the thickness direction (Z-axis), increases dramatically, potentially causing plated-through holes (PTHs) to crack due to stress.

-

Unstable Electrical Performance: The dielectric constant and loss factor may change, affecting signal integrity.

-

Delamination and Blistering: During high-temperature processes like reflow or wave soldering, the laminate may delaminate.

-

Therefore, the Tg value is a core indicator for measuring the heat resistance and reliability of PCB materials.

2. Tg170 PCB: Definition and Implications

Tg170 PCB refers to a circuit board manufactured using a substrate whose glass transition temperature reaches 170°C. According to the IPC-4101 standard, this is a defined high-Tg material grade.

-

Standard FR-4: Tg is typically in the range of 130°C - 150°C.

-

Mid-Tg FR-4: Tg is around 150°C.

-

High-Tg FR-4: Tg ≥ 170°C, with Tg170 being a mainstream choice within this category.

This means that Tg170 PCBs can maintain their structural stability and electrical performance in environments up to 170°C, far exceeding the capabilities of standard materials.

3. Prominent Advantages of Tg170 PCB

Choosing Tg170 PCB equips your product with the following robust characteristics:

-

Excellent Heat Resistance

-

Withstands Lead-Free Soldering: Lead-free soldering processes involve higher peak temperatures (can reach 260°C). Tg170 laminates can better withstand multiple reflow soldering cycles, reducing the risk of delamination and blistering.

-

Suitable for High-Temperature Applications: Ideal for use in automotive engine compartments, industrial motor drives, high-power lighting, and other high-temperature scenarios.

-

-

Higher Reliability and Stability

-

The high Tg value ensures the PCB‘s dimensional stability and mechanical strength in high-temperature operating environments, thereby enhancing the product‘s long-term service life and Mean Time Between Failures (MTBF).

-

-

Superior Moisture and Chemical Resistance

-

High-Tg materials typically have a denser cross-linked structure, making them more effective at resisting moisture and chemical solvents, resulting in more stable performance in humid environments.

-

-

Suitable for High-Layer-Count and HDI Designs

-

During the manufacturing of complex multi-layer and HDI (High-Density Interconnect) boards, which require multiple high-temperature and high-pressure processes like lamination and drilling, Tg170 laminates provide a better process window and dimensional stability, ensuring layer-to-layer registration accuracy and interconnection reliability.

-

4. Typical Application Areas for Tg170 PCB

Tg170 PCB is not suitable for all consumer electronics; its high-performance characteristics make it excel in the following high-end fields:

-

Automotive Electronics: Especially Engine Control Units (ECUs), transmission control units, power management systems, and LED headlights—components that operate for long periods in high-temperature, vibrating environments.

-

Aerospace and Defense: Aircraft control systems, radar systems, satellite communication equipment, etc., where reliability requirements are paramount.

-

Industrial Control and Power Electronics: High-power frequency converters, servo drives, power supplies, inverters, etc., where the equipment itself generates significant heat.

-

High-End Computing and Communications: High-performance servers, routers, base station equipment, where CPUs and ASICs have high power consumption, demanding excellent heat dissipation and stability from the PCB.

-

Medical Electronics: Certain implantable or high-precision diagnostic equipment require absolute reliability during sterilization or long-term operation.

5. Considerations for Selecting and Manufacturing Tg170 PCB

Despite its obvious advantages, designing and manufacturing Tg170 PCBs require some additional considerations:

-

Higher Cost: The raw material cost of high-Tg copper-clad laminates is higher than that of standard FR-4.

-

More Stringent Processing Requirements: Drilling may require more wear-resistant drill bits, and lamination parameters need to be adjusted to match the material‘s characteristics.

-

Design Compatibility: Designers need to be aware of its different CTE and take it into account during thermal and high-current design.

Therefore, a comprehensive cost-benefit-needs analysis is necessary when choosing Tg170.

Conclusion

Tg170 PCB represents a significant milestone in PCB material technology. By elevating the core parameter of glass transition temperature, it provides a solid physical foundation for the continuous evolution of electronics in terms of power, density, and reliability. In an era pursuing higher performance, more demanding applications, and longer lifespans, Tg170 is no longer an "option" but a "necessity" in many high-end and critical application fields. It is a sturdy bridge connecting innovative design with reliable reality.