China PCBA Factories: The Global Engine of Intelligent Manufacturing

Time:2025-10-29

Views:129

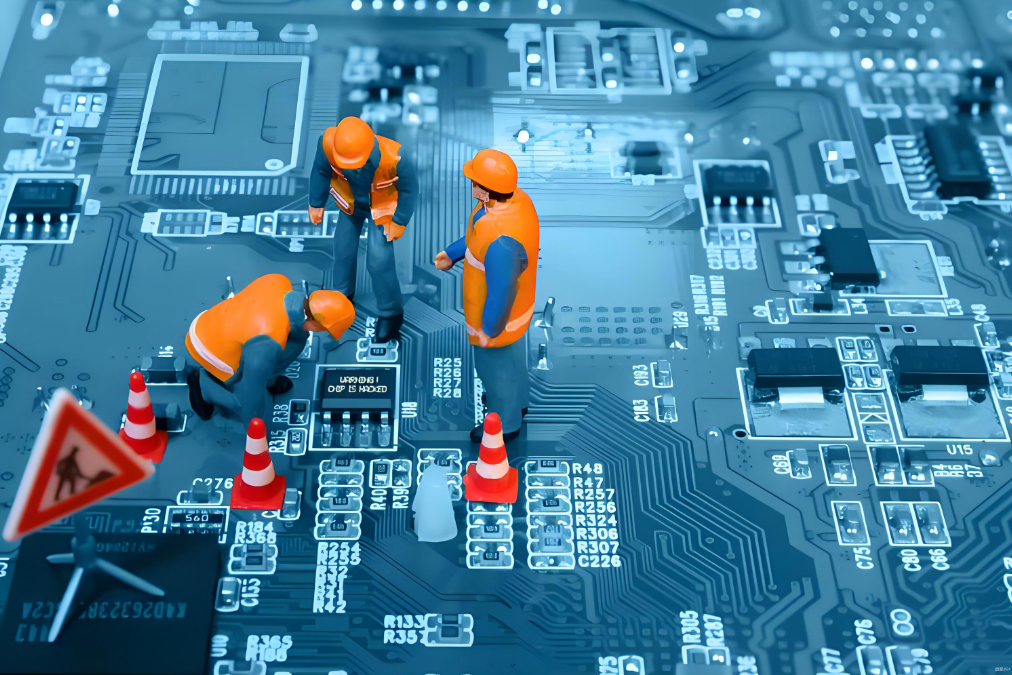

China PCBA Factories: The Global Engine of Intelligent Manufacturing

China‘s PCBA (Printed Circuit Board Assembly) industry is undergoing technological innovation and intelligent upgrades, reshaping the global electronics manufacturing landscape. As a core manufacturing segment for electronic products, China‘s PCBA industry has evolved from traditional OEM to an integrated "design-manufacturing-service" model, establishing significant competitive advantages in consumer electronics, automotive electronics, industrial control, and other fields.

Cutting-Edge Technology: From Precision Manufacturing to Intelligent Production

Space-Grade Standards

Use of radiation-resistant materials and vacuum environment processes to meet extreme application requirements for satellite terminals

Achieves a failure rate below industry average after three years of continuous operation

Medical-Grade Precision

Selective electroplating technology effectively solves signal interference issues in high-density wiring

Helps medical products like ultrasound devices pass FDA certification

Industrial-Grade Efficiency

AI vision inspection systems improve manual inspection efficiency by several times while significantly reducing defect miss rates

Fully automated production lines enable end-to-end intelligent control, with some factories recognized as national-level intelligent manufacturing demonstration sites

Regional Clusters and Industry Leaders

Shenzhen Innovation Ecosystem

Shenzhen Cirket Electronics Co., Ltd.

Implements "Innovative Symbiosis" model, deeply involved in client projects from design stage

Annual production capacity exceeds 2 million units, with leading multi-layer PCB technology

6 fully automated production lines serve brands like Apple, BYD, and Toyota

Yangtze River Delta & Pearl River Delta Synergy

Factories in Suzhou, Dongguan, etc., focus on automotive electronics and industrial control

Some enterprises achieve 30% energy savings and 25% operational cost reduction through intelligent upgrades

Industry Upgrading Path

Service Model Innovation

Shifts from "OEM processing" to "design + manufacturing" to shorten client R&D cycles

Leading factories offer one-stop services from PCB design to functional testing

Green Intelligent Transformation

Intelligent upgrades reduce energy consumption and carbon emissions

Some factories achieve over 90% waste material recycling rate

Future Outlook

Driven by technologies like 5G and IoT, China‘s PCBA factories are consolidating their position as global electronics manufacturing hubs through a "technology + service" dual strategy. Breakthroughs in high-end fields like aerospace and medical electronics will further strengthen China‘s leadership in the global industrial chain.