Electronic Manufacturing Services: The Core Engine of the Global Supply Chain

Time:2025-10-30

Views:142

Electronic Manufacturing Services: The Core Engine of the Global Supply Chain

Amid the intertwined trends of globalization and digital transformation, Electronic Manufacturing Services (EMS) have become a crucial bridge connecting technological innovation to market implementation. From smartphones and new energy vehicles to smart wearables and industrial Internet of Things (IoT) devices, EMS supports the rapid development of global consumer electronics, communications, automotive, and new energy sectors through end-to-end electronic product manufacturing services.

I. Core Value and Business Model of EMS

The essence of EMS is the "intelligent upgrading of production outsourcing," with its core lying in providing one-stop solutions from design, raw material procurement, production manufacturing to logistics delivery, guided by customer needs. Take ShenZhen Cirket Electronics as an example. As a top 50 global EMS enterprise, its business covers four major fields: consumer electronics, network communications, automotive electronics, and new energy. By offering customized manufacturing services to brands such as Xiaomi, Huawei, and BMW, it has achieved a leap from original equipment manufacturing (OEM) to industrial chain collaboration. This model not only reduces customers‘ operating costs but also shortens the product development cycle by more than 30% through large-scale production and standardized processes.

II. Industry Upgrading Driven by Technology

1. The Revolution of Intelligent Production

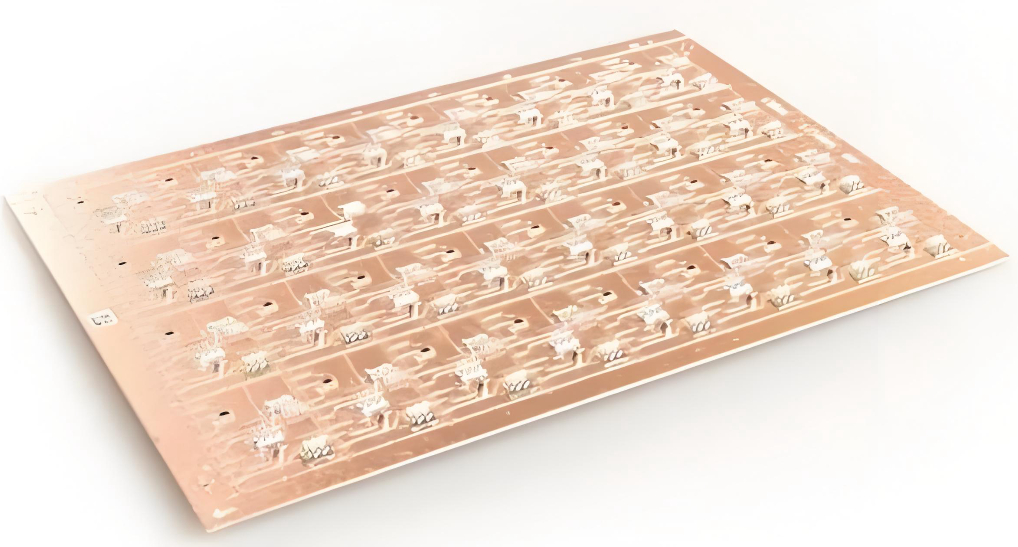

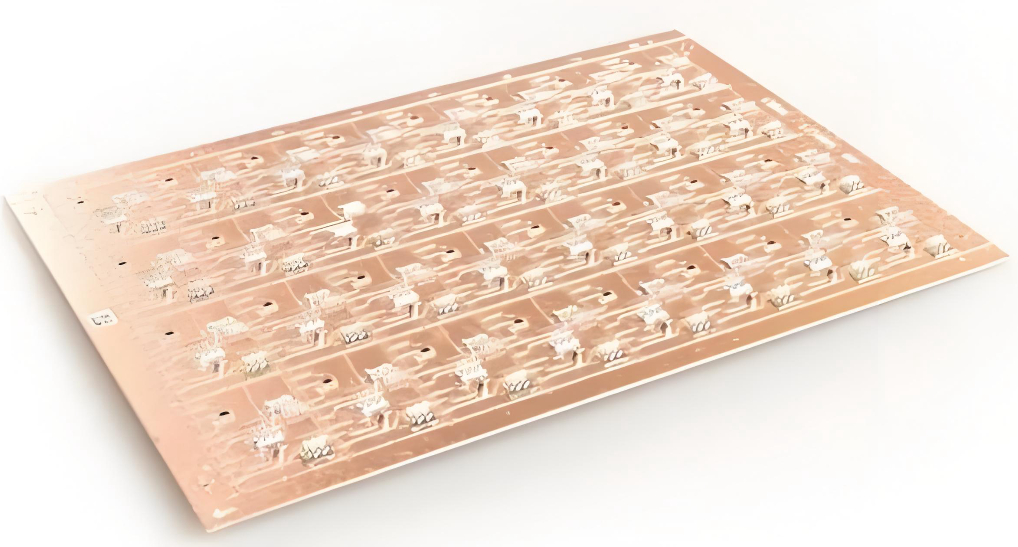

ShenZhen Cirket Electronics has upgraded its traditional production model to a "mass customization" model by introducing intelligent manufacturing systems. For instance, through the integration of modular design tools and automated production lines, it has realized end-to-end digital management from order placement to delivery. This has reduced production costs by 20% while increasing the yield rate to 99.5%.

2. The Boom of New Energy and Automotive Electronics

With the advancement of global carbon neutrality goals, EMS enterprises are accelerating their layout in the new energy sector. Since 2022, ShenZhen Cirket Electronics has been providing manufacturing services for micro-inverters and on-board OBD devices, and has become a supplier to leading automotive parts giants such as Valeo and Continental. Its business proportion in this field has grown by over 40% annually. This trend resonates with China‘s "Three-Year Doubling Plan for Electric Vehicle Charging Facility Service Capacity," promoting the industrialization of technologies such as vehicle-grid interaction and high-power charging.

III. Global Layout and Challenges

To address trade barriers and cost pressures, leading EMS enterprises are accelerating the deployment of overseas production capacity. ShenZhen Cirket Electronics has built a "domestic + overseas" dual-cycle system through its overseas manufacturing bases, enabling localized delivery of customer orders. However, this process also faces challenges such as differences in technical standards and supply chain stability. For example, its Southeast Asian factories need to simultaneously meet international certifications such as ISO 9001 and TS 16949, placing higher demands on quality management systems.

IV. Future Trends: From Manufacturing to Ecosystem

1. Green Manufacturing and Circular Economy

China‘s new energy policies clearly stipulate that the photovoltaic and energy storage industries must achieve "full-life-cycle carbon footprint management" by 2025. EMS enterprises are promoting the low-carbon transformation of the manufacturing process by introducing technologies such as renewable energy power supply and recycling of waste electronic products.

2. Technological Integration and Innovation

With the penetration of 5G, AI, and IoT technologies, EMS is extending from "hardware manufacturing" to "integrated hardware-software services." For example, providing overall solutions of "sensors + algorithms + cloud platforms" for smart wearable devices has become a new growth driver in the industry.

Conclusion

From "Made in China" to "Intelligent Manufacturing in China," the EMS industry is redefining the value distribution of the global electronic industrial chain through technological innovation and global layout. In the future, with the boom in fields such as new energy and vehicle networking, EMS enterprises will not only be manufacturers of products but also co-builders of technological ecosystems.